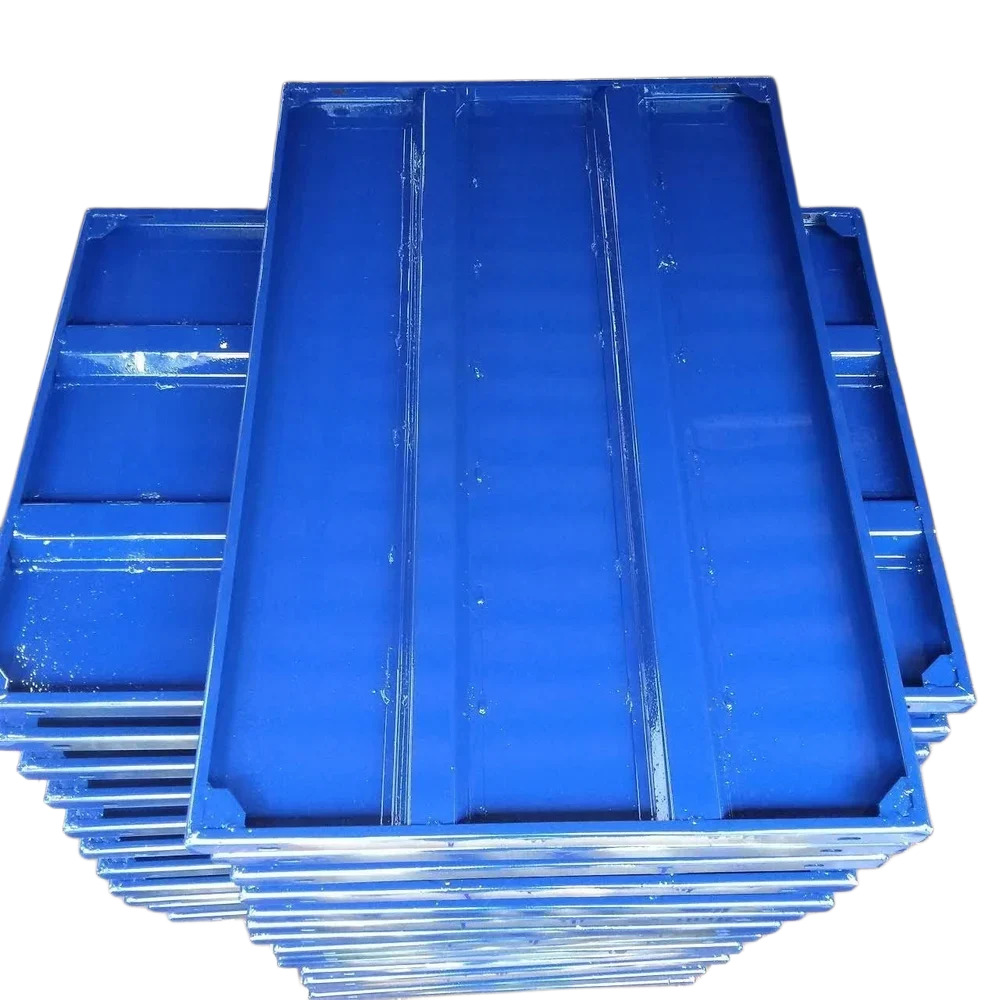

Durable iron centering sheets (also known as centering plates or steel formwork sheets) are robust, reusable components primarily used in construction to provide temporary support for wet concrete until it cures and gains sufficient strength. They are engineered for high strength, longevity, and efficiency in forming concrete structures like slabs, beams, and columns. Key Features and Specifications Material: Although often referred to as “iron,“ these sheets are typically made from high-strength mild steel (MS) due to steel's superior tensile strength and durability in construction applications. Design: They usually feature welded or riveted angles (e.g., 35x35x5 mm thick) along the edges to enhance structural integrity and prevent deformation under heavy loads. Dimensions: Standard Sizes: Common sizes include 600 x 900 mm (2 x 3 feet) and 600 x 1250 mm. Thickness: Available in various thicknesses, typically ranging from 2 mm to 10 mm or more, depending on load requirements. Surface Finish: To ensure longevity and protect against harsh environmental conditions, they often have a protective finish, such as red oxide paint, color coating, or hot-dip galvanization, which makes them corrosion-resistant. Load-Bearing Capacity: They are designed with high load-bearing capacity to safely support the substantial weight of wet concrete and construction activities. Benefits in Construction Durability and Reusability: Their primary advantage is exceptional durability, allowing for multiple reuses (often over 100 times, compared to a few for wood), which makes them highly cost-effective in the long run. Structural Integrity: They ensure precise shaping, alignment, and structural integrity of concrete elements by providing a stable and rigid formwork system. Efficiency: The modular and often lightweight-yet-rigid design of modern steel sheets allows for faster assembly and dismantling compared to traditional wooden formwork, which speeds up project timelines and reduces labor costs. Safety: The stable platform they create enhances safety on construction sites by minimizing the risk of formwork failure during the concrete pouring and curing phases. Versatility: They can be used in a wide range of applications, including high-rise buildings, bridges, tunnels, industrial facilities, and residential projects. Limitations Weight: They are heavier than alternatives like plywood or plastic, which can slow down manual handling and may require mechanical assistance in large projects. Maintenance: They require regular cleaning and oiling (or proper storage for painted/galvanized versions) to prevent rust and ensure a smooth concrete finish for repeated use.